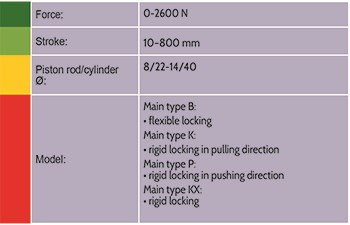

Lockable gas spring type B:

The gas spring piston can be progressively locked over the entire length of the stroke. B-type spring with flexible locking when pulling out and pushing in. Movement range of the release button < 1 mm.

Operation:

In type B locking gas springs, locking is achieved by gas and is flexible in both directions. When the valve is closed, the spring can be locked in any position along the travel length, but the lock is elastic. Depending on the force applied, the lock will retract when the gas spring is locked. Even when the gas spring is locked, it provides comfortable damping in both directions.

Lockable gas spring type K:

The gas spring piston can be progressively locked over the entire length of the stroke. K-type spring with a rigid lock-out feature. Almost fixed when pushed in.

Operation:

For K-type gas springs, the locking function takes place in an oil chamber separated from the gas by a floating piston. When force is applied to the locked spring by pushing it outwards, the lock remains rigid because there is only oil between the piston and the end piece. The locking force remains completely rigid until the mechanical strength of the spring. If the force is applied in the compression direction, the spring remains rigid until the compression force of the floating piston is overcome.

Lockable gas spring type P:

The gas spring piston can be progressively locked over the entire length of the stroke. P-type spring, rigidly locked when pushed in and almost rigid when pulled out.

Lockable gas spring type U:

The U-type gas spring can only be locked in one direction. When the piston moves outward, the lock is rigid; it cannot be locked by pushing the plunger inward. By pushing the piston inward, the spring acts like a gas spring. Therefore, the spring can be installed without having to release it by pushing the piston inwards like a gas spring. Typical applications: Monitor height adjustment.

74860

74860 gas-5

gas-5 mini-gas

mini-gas